Flexographic Label Printing

Flexographic Printing for Custom Labels, Shrink Sleeves, Flexible Packets, And More

Flexographic printing is perfect for handling a high output level for label quantities in the thousands and millions. This printing method works with an assortment of materials and technical capabilities such as pressure-sensitive labels, shrink sleeves, flexible packaging, cold foil stamping, and much more. After the initial setup costs, flexographic printing becomes more cost-effective with the more labels you order since our flexographic presses typically run several hundred feet of material per minute. Although setting up a flexographic press often takes more time than a digital press, one of the biggest advantages that it offers is that once a job sets up on the press, it runs very quickly relative to the speed of running a job on a digital press.

Flexographic Materials and Capabilities

Flexographic printing accommodates a diverse range of label products and materials. For example, we offer coupon label printing, removable adhesive labels, and multi-layer labels. Our presses are capable of printing spot colors, specialized inks, white underprinting, and unique finishes. We even have a 12-color flexographic press which allows for even more customization options! Flexographic presses modify to meet the needs of many different label projects and achieve optimal results.

Download our white paper to see how to attract more customers by upgrading your custom labels!

Further Reading

Call today to speak with a specialist about your unique project.

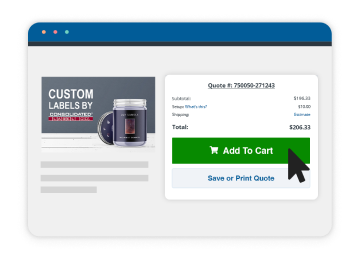

Or try our online instant pricing calculator.

Get Pricing