Our guides – Label Adhesives Guide Part 1: Types & Properties and Part 2: Performance Factors – covered all sorts of technical stuff from adhesive types, various properties, and factors that affect performance. It’s a lot to remember, so we’ve created this quick reference guide of the six things you MUST do to better ensure your labels will work exactly as you expect.

Know what you need and have a goal.

We carry a wide range of materials because we print a wide variety of labels for a wide variety of industries. Simple labeling projects can get by with popular, cost-effective stock combinations, like semi-gloss paper with a permanent adhesive. More complex projects may require special material and adhesive combinations. It really depends on what’s most important to you. Is your priority an eye-catching look, easy removability, label flexibility, moisture resistance, or some other unique performance feature?

Consider where your label will live.

The conditions your labels will endure during and after application are big considerations. Direct contact with moisture, storage temperature, the presence of airborne particles, and other environmental factors play a significant role in the label’s life. When selecting label materials, get input from anyone that comes into contact with the label (production, shipping/receiving, packaging and even sales). They can you get a better picture of what your labels will face, both in your facility and out in the world.

Take shape into account.

Is there a curved surface on your package? If so, curves can be tricky because they can cause labels to crease or flag (i.e. when the edge of a label lifts up) if a few considerations are not made. Thinner, more flexible materials and aggressive adhesives are available to help solve the curved surface dilemma. For extreme curves and small diameters, a shrink sleeve label could be your best option. These full-body labels wrap all the way around a container for 360-degree coverage.

Don’t forget the substrate.

The material/surface your labels will be applied to can throw a wrench into your plans if not factored into the equation. The substrate’s composition (i.e. glass, plastic, metal, etc.) can even react differently to certain adhesive types. Labels stick best to clean, smooth, non-porous surfaces, but having that “perfect” surface isn’t always an option. What if your substrate only has two of these qualities – or none at all? If unclean surfaces are unavoidable, or the surface is rough instead of smooth, then it’s a good idea to go with a permanent label adhesive with high initial tack.

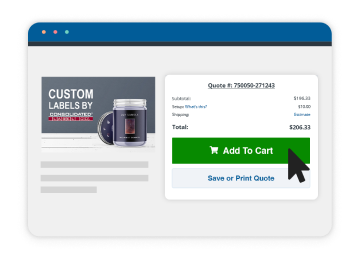

Give your label supplier (that would be us!) all the details.

We ask all sorts of questions to make sure that our customer’s labels are printed on materials that best fit their project’s needs. Having your project’s details ready-at-hand for your rep is the best way to ensure that everyone is on the same page, and your labels meet your expectations. When in doubt, send us your container so we can see first-hand what you’re working with. We can test some label materials on-site and give you our best recommendation. (See the next bullet point!)

Test before you invest.

Complex labeling jobs or large orders should ALWAYS test label adhesives and materials before taking the final plunge. Testing the materials can help you avoid wasting precious time and resources, especially if you have special labeling needs that require more expensive materials or printing processes. When testing, note how the materials interact with the substrate, the application method, your production environment, final service conditions, and overall packaging.

Having a better understanding of your overall goals can provide a solid foundation for every type of labeling project. As always, our label experts are happy to discuss your project’s requirements so you get labels that not only stick properly but look great too.