There are a lot of great things about digital label printing like quick turnaround and extremely high print quality, but what about the advantages of using our newest digital label press? Get a behind-the-scenes look at the latest addition to our production lineup to see how you can benefit from our biggest digital press.

Benefits Of Our New Digital Press

Earlier this year, we purchased a new digital press to expand our production capacity, reduce set-up costs and waste, as well as improve overall turnaround time. We considered a few different options during an exhaustive search process but ended up selecting the HP Indigo 8000 because it was a win-win for both us and you, the customer.

Reasons why we went with the HP Indigo 8000 digital press:

- Prints bigger runs with better consistency: The 8000 digital press allows us to print larger runs more efficiently than on the 6000 series digital presses – this also reduces the waste normally associated with these larger projects.

- Able to print more versions within a run: Whether it’s multiple label versions or variable data, having a larger press allows us to print more in a run.

- Less waste than flexographic: Orders that were only able to be print on a flexographic press can be switched to the 8000 digital press which produces less setup waste.

- Up to double the speed of other narrow-web digital presses: Faster printing speed allows us to print more thereby shortening turnaround times.

Investing in digital printing not only makes sense for our business and yours, it’s also where the label industry is heading.

Digital Label Printing Continues To Grow

Traditional printing methods (like flexographic and offset) are losing market share to digital due to its ability to produce high quality, cost-effective labels for smaller label buyers. Unlike flexographic presses that uses polymer plates to transfer ink onto the label material, digital presses use dots of ink to recreate an image from a digital file – the process is similar to how your desktop printer works. Since there’s less press setup, it’s less expensive to print smaller label quantities (known as ‘short run labels’), multiple designs, or variable data.

Now, we’re not saying flexographic will go away because there will always be high volume label buyers who need it. But with markets becoming more segmented and the rise of independent brands, more are turning to digital printing because it’s an economical solution for printing smaller label quantities for niche markets.

Different ways brands are targeting consumers with digitally printed labels:

- Unique designs for different flavors, scents, etc.

- Multiple languages

- Regional promotions

- Seasonal products

- QR codes

- Coupons

- Personalized messages (e.g. Coca-Cola’s “Share a Coke” campaign)

- Harvesting and cultivating information for product ingredients

- Gluten-free, ‘organic,’ or ‘natural’ versions of a product

Digital’s agility not only helps brands get quality and cost-effective short run labels, it helps them push their product to market more quickly. As market segmentation increases, businesses will find that digital label printing is key to achieving sales goals.

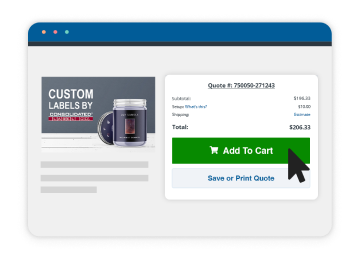

Get started today on your digitally printed labels by getting an online quote or contacting us at 1-800-475-2235 or sales@consolidatedlabel.com.