Custom Label Printing Services

Custom Label Printing Methods

For over 30 years, Consolidated Label has been manufacturing high quality custom labels because we’re passionate about making our customers look good. We’ve printed billions of labels for a variety of markets and applications – innovating new printing techniques along the way – so you always get the label look you want for the right price.

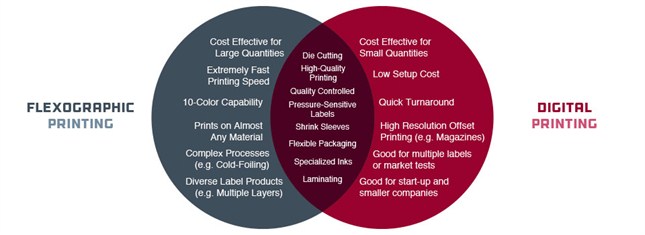

Our printing methods include flexographic and digital printing. Both methods produce high-quality labels, and their combined capabilities allow us to create a large variety of label styles and products.

Flexographic Printing

- Flexographic label presses use flexible printing plates to transfer the inks onto your labels. Because of this, flexographic presses require initial setup costs. This includes preparing artwork, plate-making, and registering of the printing plates when setting up your labels on the press.

- Flexographic label printing is ideal for larger runs of custom labels because flexographic presses can print high volumes at a faster rate than digital. This printing method can also handle a wide assortment of materials and technical capabilities. For instance, we can produce pressure-sensitive labels, shrink sleeves, and holographic labels all on the same press.

Digital Printing

- Digitally printed labels are vibrant, high-quality labels. We use only the best digital presses designed precisely for label production, which guarantee the best in quality and consistency.

- The setup costs for digital labels can be an ideal solution for smaller companies. However, it’s also ideal for those wishing to purchase a small quantity of custom labels. Also, the turnaround time for digital labels is quicker because it bypasses the setup time needed to create printing plates.

Start on your labels with our instant online quote tool! For more information, please call 1-800-475-2235 or email sales@consolidatedlabel.com.

Further Reading

Call today to speak with a specialist about your unique project.

Or try our online instant pricing calculator.

Get Pricing